Valid Magnetics Displacement Correction Device / Web Guide for Masks Production Machines–Edge Position Control System for Nonwoven Lines – Automation Component Supplier

Woven fabrics are frequently displaced when feeding into the machine to cause failure in production and the waste of materials.

With our unique and own developed correction device which is specialized for mask production machines, the pass rate and efficiency are greatly improved!

Features:

- Rapid response by high speed CPU

- Support Ultrasonic sensors, opto sensors to deal with different materials

- Top quality of bearing with high precision (+/- 1mm) and low noise

- Durable and long working life

- Easy to be installed

Specifications:

| Voltage | DC24V, 48W power supply |

| Control accuracy | 1mm |

| Control method | Closed-loop control |

| Control response | 0.01sec |

| Environment | 0-40 |

Three sizes available:

Sensor Specifications:

| Tracing method | Edge tracing |

| Power input | DC10~30V |

| Output signal | Analog 0-5V double channel NPN type |

| Testing scope | 8mm(+/-4) |

| Adjustable accuracy | (+/-0.02mm) |

| Testing method | Opto-electrical sensing |

| Wavelength / Response frequency | 100KHz / 1K HZ |

| Protection level | lp54 |

| Weight | 250g |

| Environment | (-10 to 80 C, RH90%) |

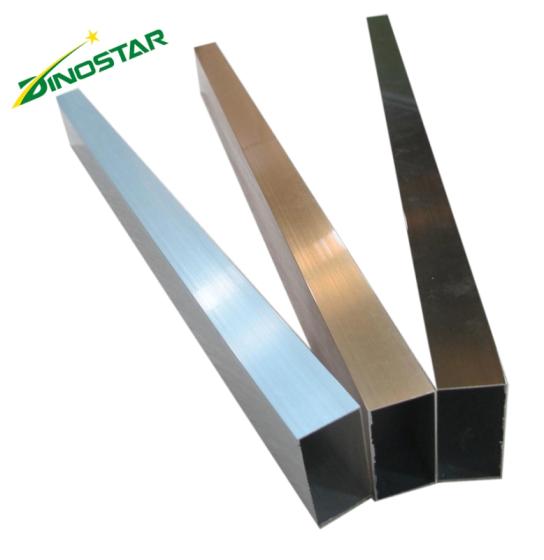

| Outcase material | Aluminium alloy |

| Material calibration | Necessary |

Simple Connection Diagram:

Reposted for informational purposes only. Views are not ours. Stay tuned for more.